PCB manufacturing

-

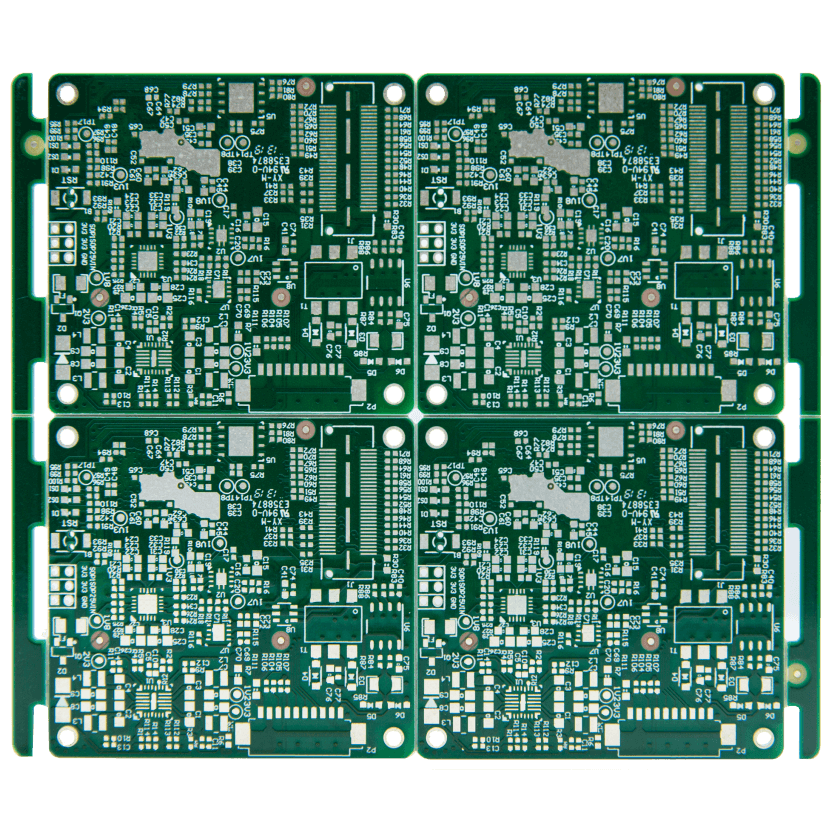

OEM PCBA Clone Assembly Service Other PCB & PCBA Custom Electronics PCB Circuit Board

Application:Aerospace, BMS, Communication, Computer, Consumer Electronics, Home appliance, LED, Medical Instruments, Motherboard, Smart electronics, Wireless charging

Feature:Fexible PCB, High density PCB

Insulation Materials:Epoxy Resin, Metal Composite Materials, Organic Resin

Material:Aluminum Covered Copper Foil Layer, Complex, Fiberglass Epoxy, Fiberglass Epoxy Resin & Polyimide Resin, Paper Phenolic Copper Foil Substrate, Synthetic Fiber

Processing Technology:Delay Pressure Foil, Electrolytic Foil

-

Mobile outdoor energy storage power supply solution control motherboard PCBA circuit board

The new energy control board has the characteristics of high integration, intelligent control, protection functions, communication functions, energy saving and environmental protection, high reliability, strong safety and easy maintenance. It is an important part of new energy equipment. Its performance requirements include voltage resistance, current resistance, temperature resistance, humidity resistance, corrosion resistance, durability and other characteristics to ensure the stability and reliability of the equipment. At the same time, new energy control boards also need to have good anti-interference capabilities.

It is widely used in renewable energy, electric vehicles, smart grids and other fields. It is one of the important technologies to achieve efficient utilization of new energy and energy conservation and emission reduction to cope with complex working environments. -

Car charging pile motherboard control board SMT chip processing PCBA processing Charging pile solution circuit board manufacturer

The car charging pile PCBA motherboard is the core component used to control the charging pile.

It has a variety of functions. Here is a brief introduction to its main features:

Powerful processing capability: The PCBA motherboard is equipped with a high-performance microprocessor, which can quickly handle various charging control tasks and ensure the safety and stability of the charging process.

Rich interface design: PCBA motherboard provides a variety of interfaces, such as power interfaces, communication interfaces, etc., which can meet the data transmission and signal interaction needs between charging piles, vehicles and other equipment.

Intelligent charging control: The PCBA motherboard can intelligently control the charging current and voltage according to the battery power status and charging needs to avoid battery overcharging or undercharging, effectively extending battery life.

Complete protection functions: The PCBA motherboard integrates a variety of protection functions, such as over-current protection, over-voltage protection, under-voltage protection, etc., which can cut off the power supply in time when abnormal conditions occur to ensure the normal operation of the system. Safety of the charging process.

Energy saving and environmental protection: The PCBA motherboard adopts an energy-saving design, which can adjust the power supply current and voltage according to actual needs, effectively reducing energy consumption and reducing the impact on the environment.

Easy to maintain and upgrade: PCBA motherboard has good scalability and compatibility, which facilitates later maintenance and upgrades, and can adapt to changes in different models and different charging needs.

-

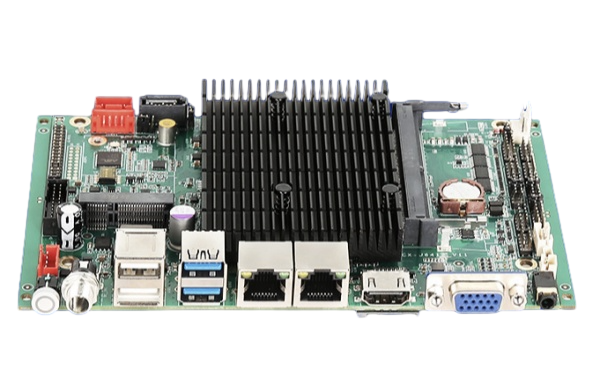

Customizable industrial grade control panel

Industrial-grade motherboard PCBA needs to have excellent performance and stability and is suitable for various industrial automation, robots, medical equipment and other applications. Its highly reliable connection and layout design ensures that the motherboard will not malfunction during long-term operation, improving the overall performance and service life of the device.

In addition, the motherboard PCBA has good compatibility and scalability, allowing it to connect and expand with various peripherals and sensors to meet the needs of different application scenarios. At the same time, its easy maintenance and upgrade features reduce usage costs and maintenance difficulties.

-

Military aerospace pcb Dedicated printed circuit boards designed for military aerospace applications

1.Application: UAV (high frequency mixed pressure)

Number of floors: 4

Plate thickness: 0.8mm

Line width line distance: 2.5/2.5mil

Surface treatment: Tin

-

Medical equipment PCB Medical electronics

1.Application: electrocardiogram detector

Number of floors: 8

Plate thickness: 1.2mm

Line width line distance: 3/3mil

Surface treatment: Sunk gold

-

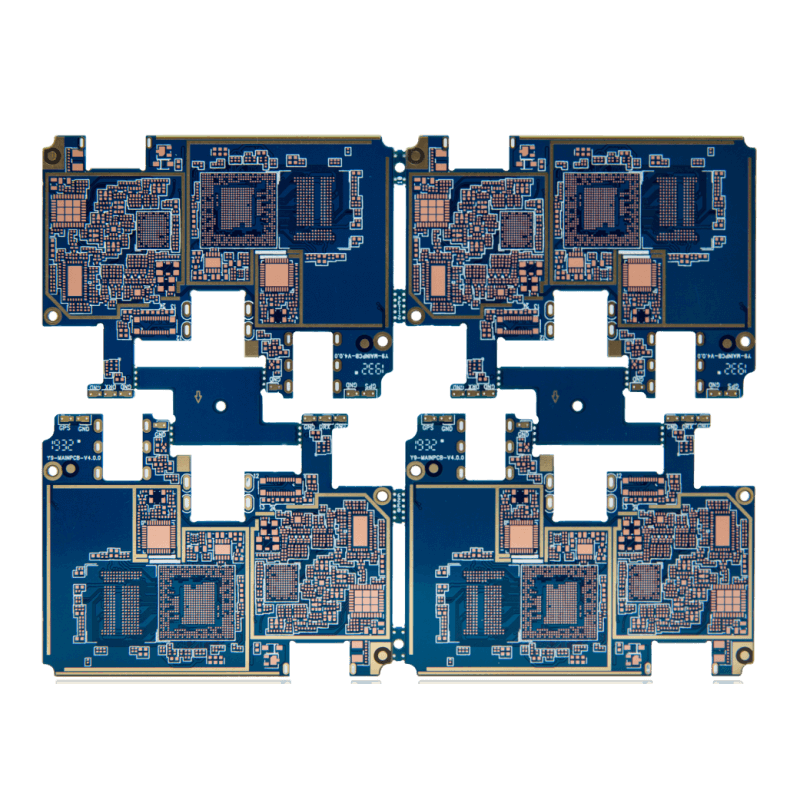

Intelligent communication module PCB Printed circuit boards designed for intelligent communication modules used in various applications such as Internet of Things (IoT), wireless communication and data transmission

1.Application: intelligent mobile terminal

Number of layers: 12 layers of 3 level HDI board

Plate thickness: 0.8mm

Line width line distance: 2/2mil

Surface treatment: gold +OSP

-

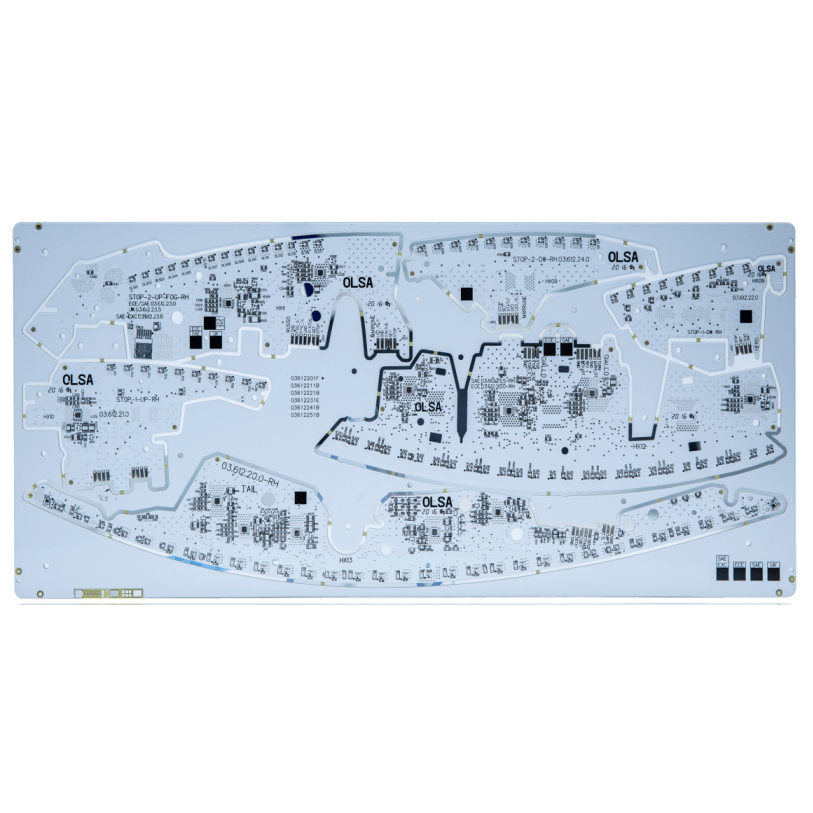

Automotive electronics PCB Commonly used in automotive entertainment systems, navigation systems, security systems, control systems

1.Application: Automotive light board (aluminum base)

Number of floors: 2

Plate thickness: 1.2mm

Line width line spacing: /

Surface treatment: Spray tin

-

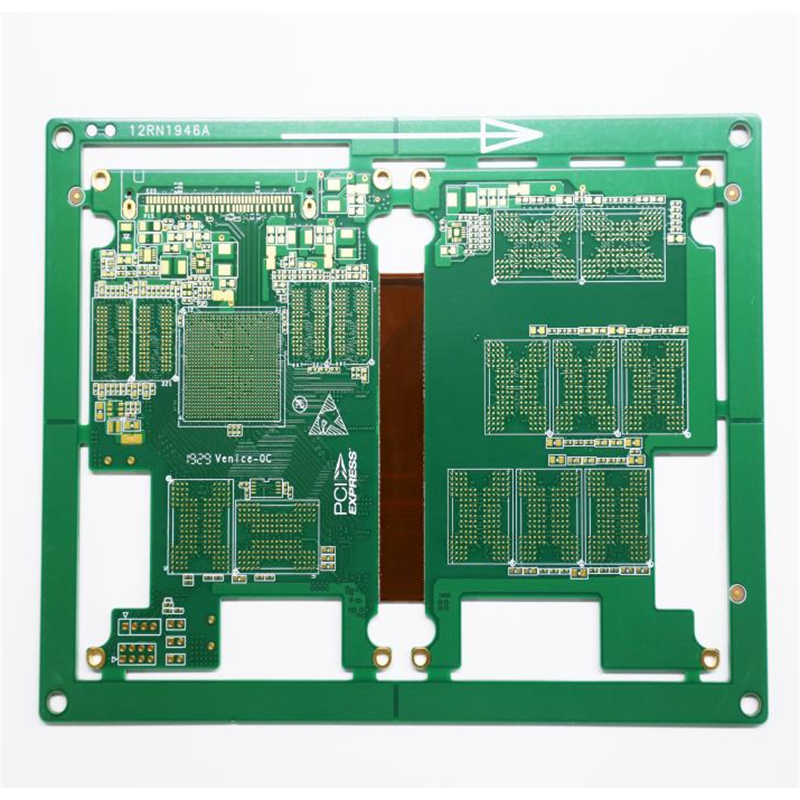

5G communication PCB Printed circuit boards used in 5G communications

1.Applications: Solid state drives

Number of layers: 12 layers (flexible 2 layers)

Minimum aperture: 0.2mm

Plate thickness: 1.6±0.16mm

Line width line distance: 3.5/4.5mil

Surface treatment: sunk nickel gold

-

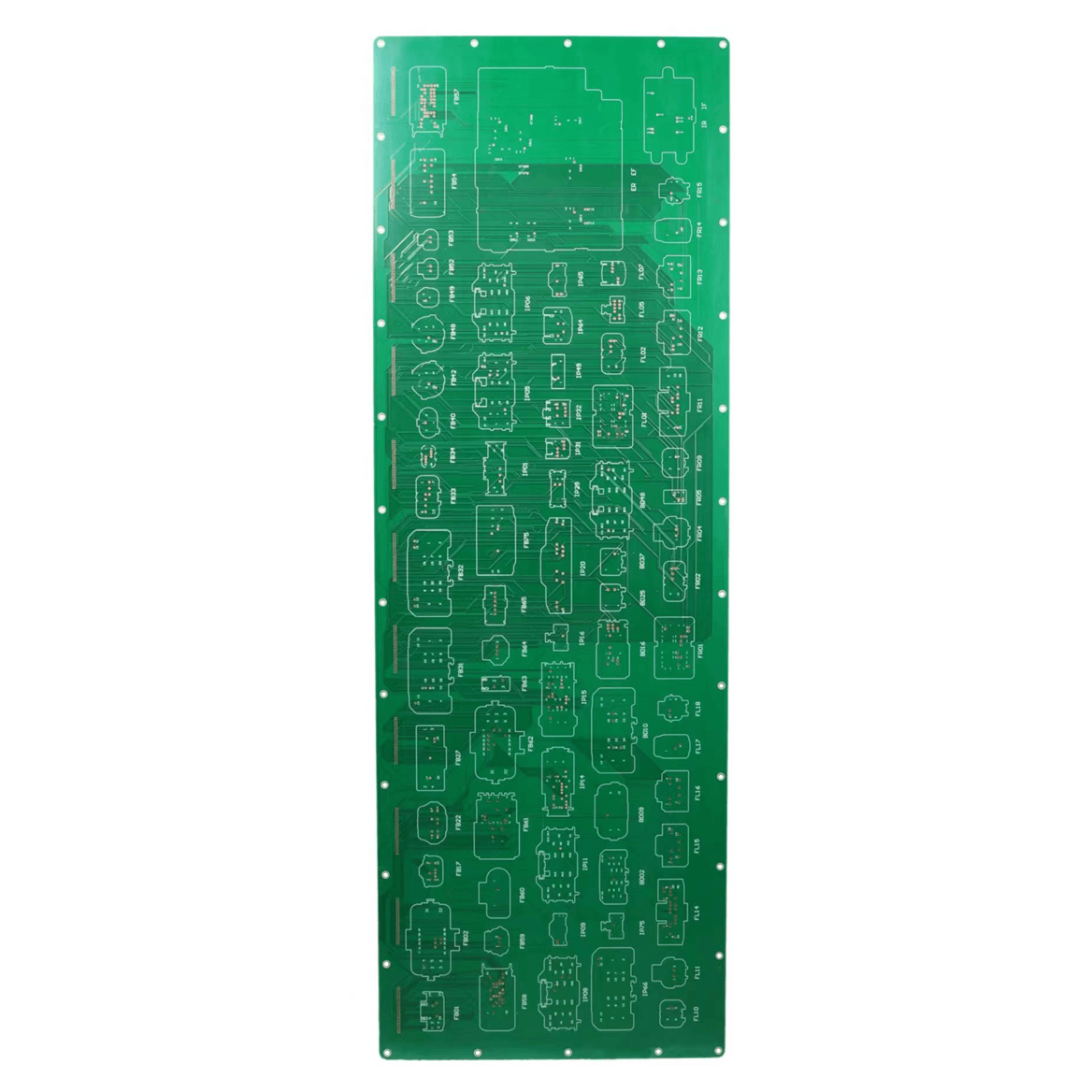

New energy PCB Printed circuit boards used in solar, wind and electric vehicles

1.Application: new energy vehicle batteries

Copper thickness: 2oz

Plate thickness: 2mm

Line width line distance: 6/6mil

Finish: Sunk gold

-

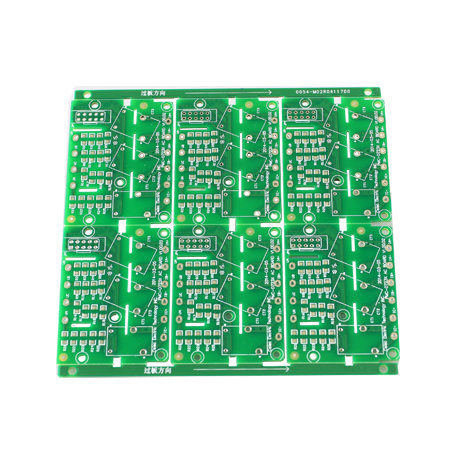

PCB Manufacturing Industrial control security

Application: Smart meters

Model number: M02R04117

Plate: Ultrasonic GW1500

Plate thickness: 1.6+/-0.14mm

Size: 131mm*137mm

Minimum aperture: 0.4mm

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Skype

-

Skype