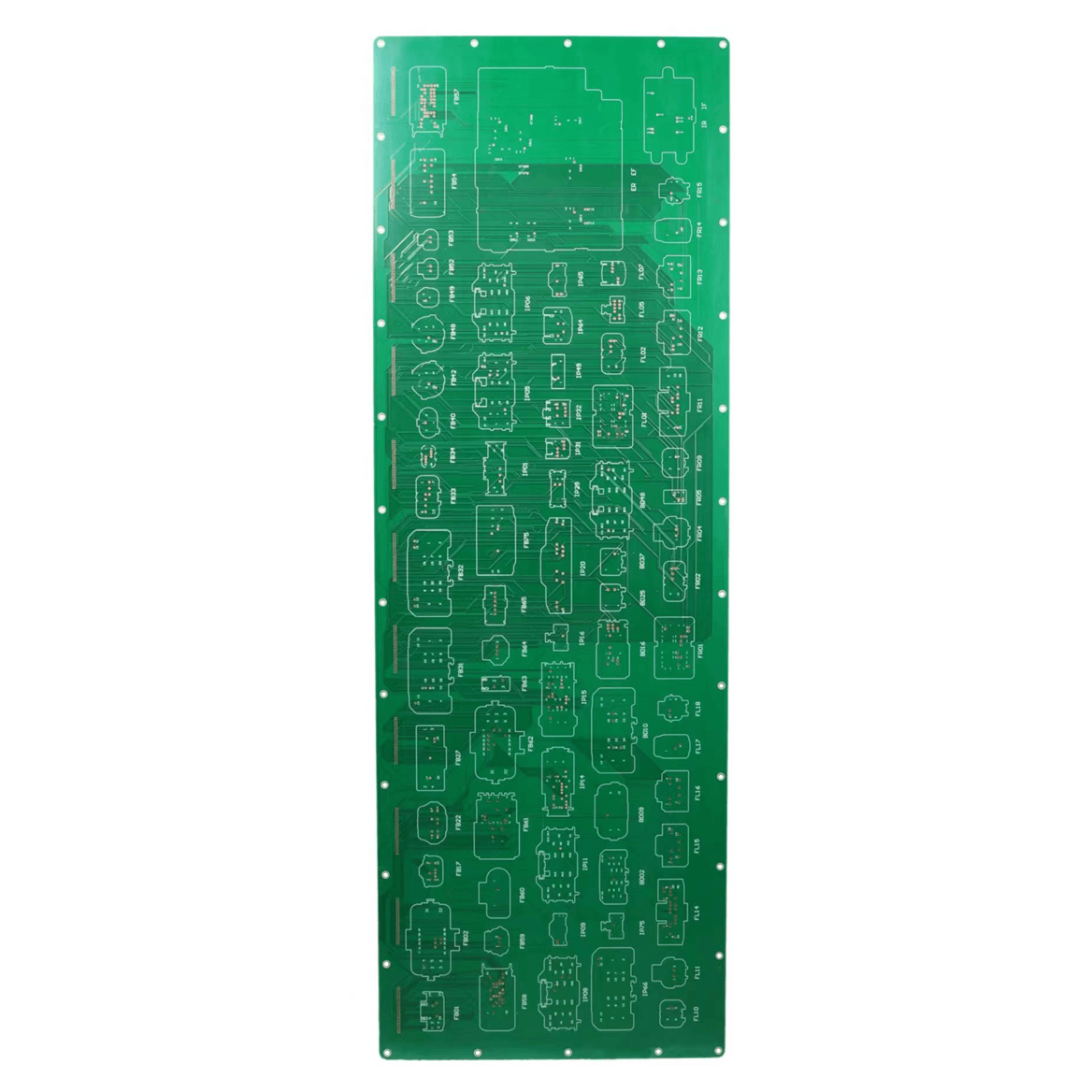

Electronic products OEM ODM PCB Assembly services

ISO9001:2015, ISO14001:2015, ISO13485, and IATF16949 certified factory.

Providing professional customized one-stop PCB assembly services for pcb assembly of electronic products in different fields.

and satisfy your diversified needs,

details are as follows.

PCB design, PCB layout, PCB fabrication

Components procurement, Component alternatives search

PCB Assembly (SMT pcb assembly & DIP pcb assembly)

Turnkey PCB assembly

Box Build assembly

Mixed technology PCB assembly

BGA / QFN assembly with X-ray inspection

IC programming

Function Testing

Wire harness and Cable assembly

High Frequency Transformer, Low Frequency Transformer

Inductor, Coil

Housing part fabrication and Mold

Conformal coating / epoxy encapsulants

Shipping arrangements

Based on your BOM, we source the components you specify. If the components you specify are out of production or the lead time is too long, our engineers will provide suitable replacement suggestions for your confirmation. All component suppliers, whether active or passive components, are authorized and reliable. Please feel free to inquire about prototyping and mass production inquiries.

Quality is our top priority.

We are an ISO9001:2015, ISO14001:2015, ISO13485, and IATF16949 certified factory that can provide PCBA manufacturing services for automotive electronics, security electronics, industrial control, smart home, medical electronics, financial equipment, communication electronics and consumer electronics…etc.

We fully meet your needs from design to market.

Our goal is to be a trusted partner, not just a PCBA manufacturer.

We have strict pcb assembly process :

1. Before starting the PCB assembly operation, prepare parts and machine settings according to the SOP process, and mass production will not begin until the first piece is produced and inspected.

2. During the PCB assembly process, manufacturing is carried out in accordance with the SOP process, and inspection stations are arranged to conduct 100% quality inspection to improve product quality.

After the pcb assembly process is completed, the packaging operation is carried out according to the SOP process, and 100% product inspection is performed before shipment.

Solder Type :

Lead-free / RoHS compliant

Testing :

AOI (Automated Optical Inspection)

X-ray Inspection

Functional testing

ICT (In-circuit testing)

Visual Inspection

Conformal coating :

dipping

spraying

brushing

selective coating

Product acceptance standards :

Comply with customer quality requirements

or in accordance with IPC-A-600, IPC-A-610 and IPC J-STD-001.

We also have an experienced R&D engineering team.

We can help you meet your needs, whether it's PCB lay-out design, component selection, develop/improving software, or mechanical design. Let you focus on selling while we help you handle tedious manufacturing process issues and even solve your engineering problems.

provide PCBA manufacturing services for automotive electronics, security electronics, industrial control, smart home, medical electronics, financial equipment, communication electronics and consumer electronics…etc.

Our advantage :

(1) Customized process capability

(2) Have an excellent management team and professional technology

(3) Have flexible production capabilities

(4) Give full play to the competitiveness of the enterprise

(5) Perfect customer service

(6) Crisis handling ability

OEM/ODM Welcome

EMS Service

Contact us now and see what we can do for you