China Double-side PCB Assembly OEM Manufacturing Electronic Component Sourcing PCBA Fabrication Turn-key Service

|

Turnkey PCBA |

PCB+components sourcing+assembly+package+shipment |

|

Assembly details |

SMT and Thru-hole, ISO SMT and DIP lines |

|

Lead Time |

Prototype: 15 work days. Mass order: 20~25 work days |

|

Testing on products |

Flying Probe Test, X-ray Inspection, AOI Test, Functional test |

|

Quantity |

Min quantity: 1pcs. Prototype, small order, mass order, all OK |

|

Files needed |

PCB: Gerber files(CAM, PCB, PCBDOC) Components: Bill of Materials(BOM list) Assembly: Pick-N-Place file |

|

PCB Panel Size |

Min size: 0.25*0.25 inches(6*6mm) Max size: 20*20 inches(500*500mm) |

|

PCB Solder Type |

Water Soluble Solder Paste, RoHS lead free |

|

Components details |

Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

|

Component package |

Cut Tape,Tube,Reels,Loose Parts |

Send us Gerber/PCB file, PCB specifications, BOM list and special assembly requirement so we will quote you the best PCBA prices within 1-3 days

PCB Bare Board:

Multi-layer,FR4,Metal,Creamic,Rogers,FPC,HDI board.

HASL,Immersion Gold/silver/Au,OSP, etc.

PCB Assembly:

9 Testing Procedures,100% Functional Tested.

BGA with X-Ray and Lead Free Assembly.

Components Sourcing:

15 Years Purchasing Experience.

Multi-channel Component Supply.

Finished products assembly:

Functional test/Programing.

Conformal Coating. Burning test.

Gift Box Packing. Storege Service.

OEM project advantages:

1. Strong engineering group

2. Efficient and simple One-stop Turnkey Service

3. Full supply chain to guarantee EB,PP&MP time

4. Design and material cost down

ODM project advantages:

1. Professional R&D team to support customers’ requirements

2. Design software platforms

3. Experienced project management

4. No MOQ and quick delivery

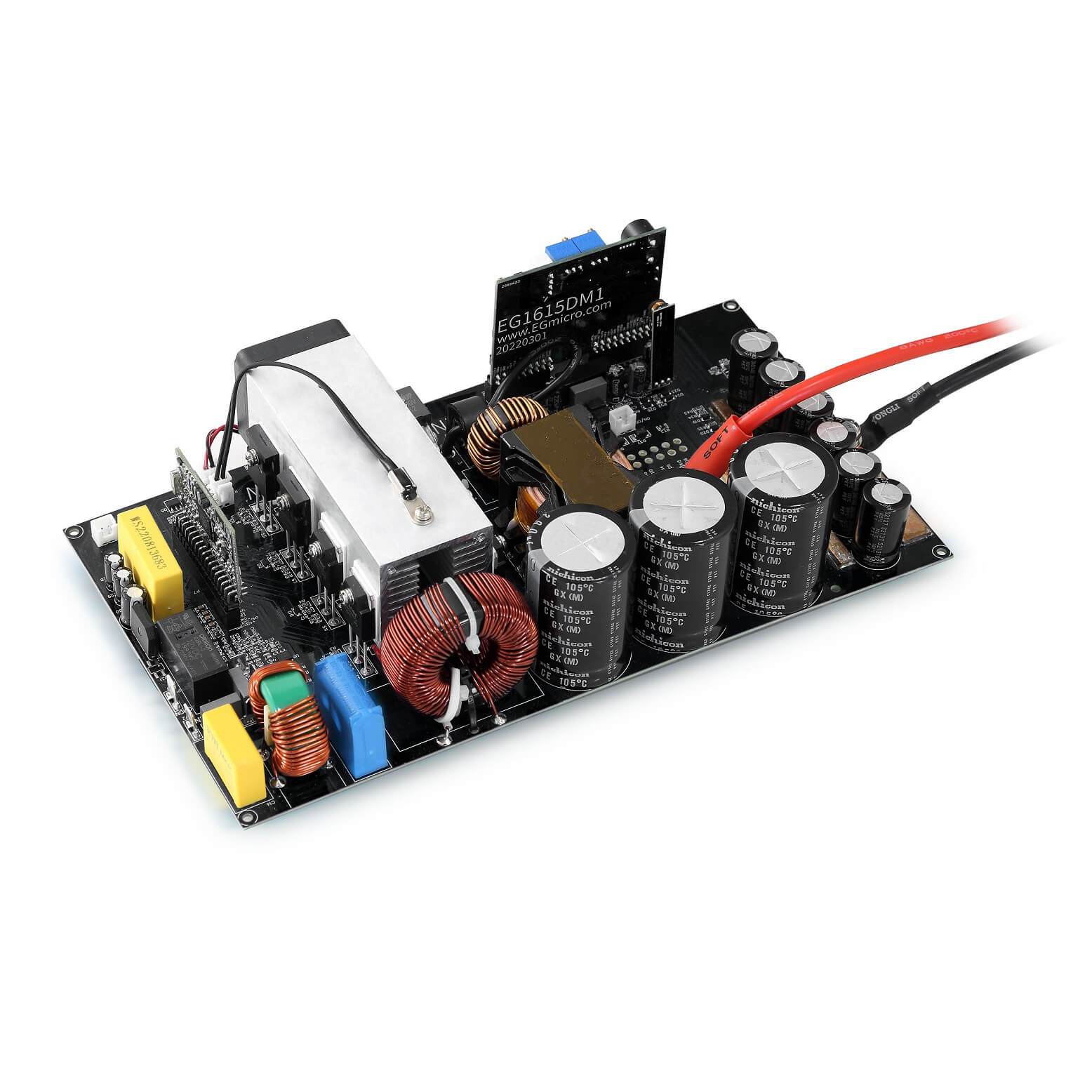

OEM products:

Millions of circuit boards are produced here every year, which provides superior service for automotive electronics, medical electronics, power communications, industrial automation, intelligent home and other industries around the world.