1、Strong PCBA R&D team, 5 engineers with more than 6 years of PCBA experience in electronic products

2、The PCBA factory is 2000 square meters with 100 employees.

3、Daily output of patch 1 million points, plug-in 200,000 points, finished PCBA product assembly and test 5,000 points.

4、With a large number of PCBA production equipment:PCB High speed SMT machine,PCB high precision multi-function SMT machine, PCB automatic printing machine, semi-automatic printing machine, hot air reflow welding, etc.

5、We have a perfect PCBA quality control system,manage the process from component purchase, warehousing to product shipment to ensure product quality.

| Turnkey PCBA |

PCB make +components sourcing+pcb assembly+pcba package |

| Assembly details |

PCBA SMT and Thru-hole, ISO SMT and DIP lines |

| Lead Time |

PCBA Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products |

Flying Probe Test, X-ray Inspection, AOI Test, Functional test |

| Quantity |

Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files needed |

PCB: Gerber files(CAM, PCB, PCBDOC) |

| Components: Bill of Materials(PCBA BOM list) |

| PCB Assembly: Pick-N-Place file |

| PCB Panel Size |

PCB Min size: 0.25*0.25 inches(6*6mm)PCB Max size: 20*20 inches(500*500mm) |

| PCB Solder Type |

Water Soluble Solder Paste, RoHS lead free |

| Components details |

Passive Down to 0201 size |

| BGA and VFBGA |

| Leadless Chip Carriers/CSP |

| Double-sided SMT Assembly |

| Fine Pitch to 0.8mils |

| BGA Repair and Reball |

| Part Removal and Replacement |

| Component package |

Cut Tape,Tube,Reels,Loose Parts |

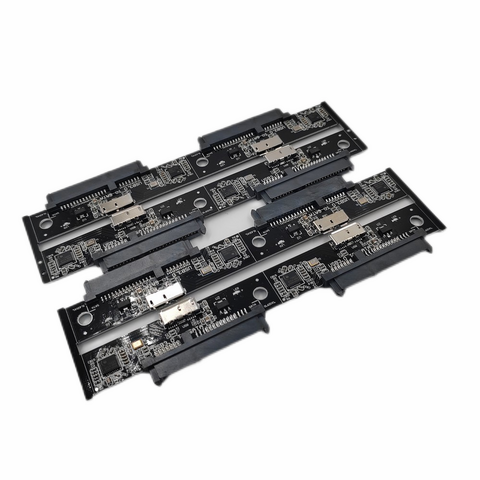

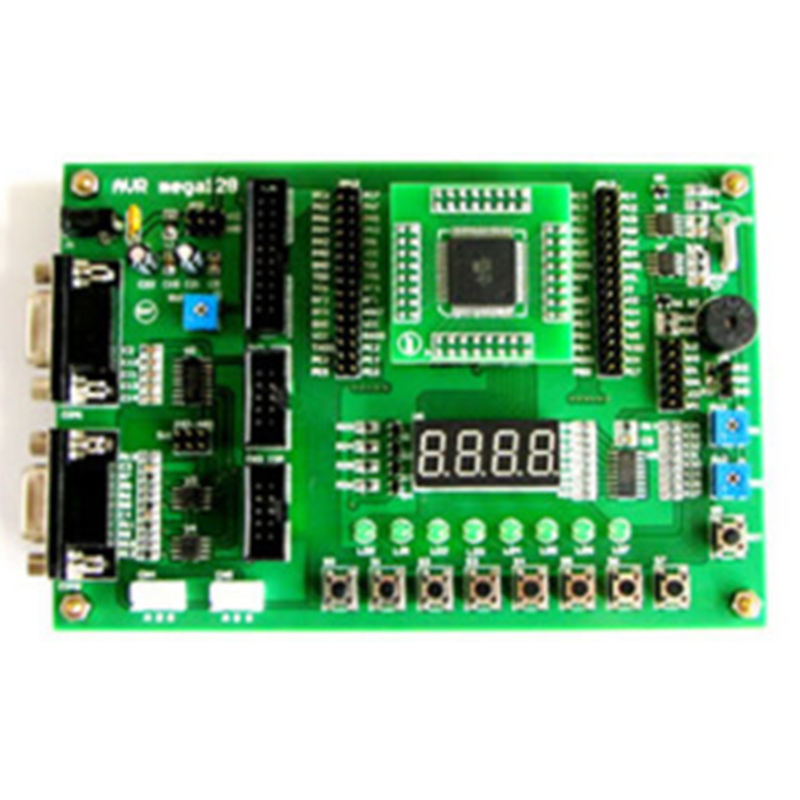

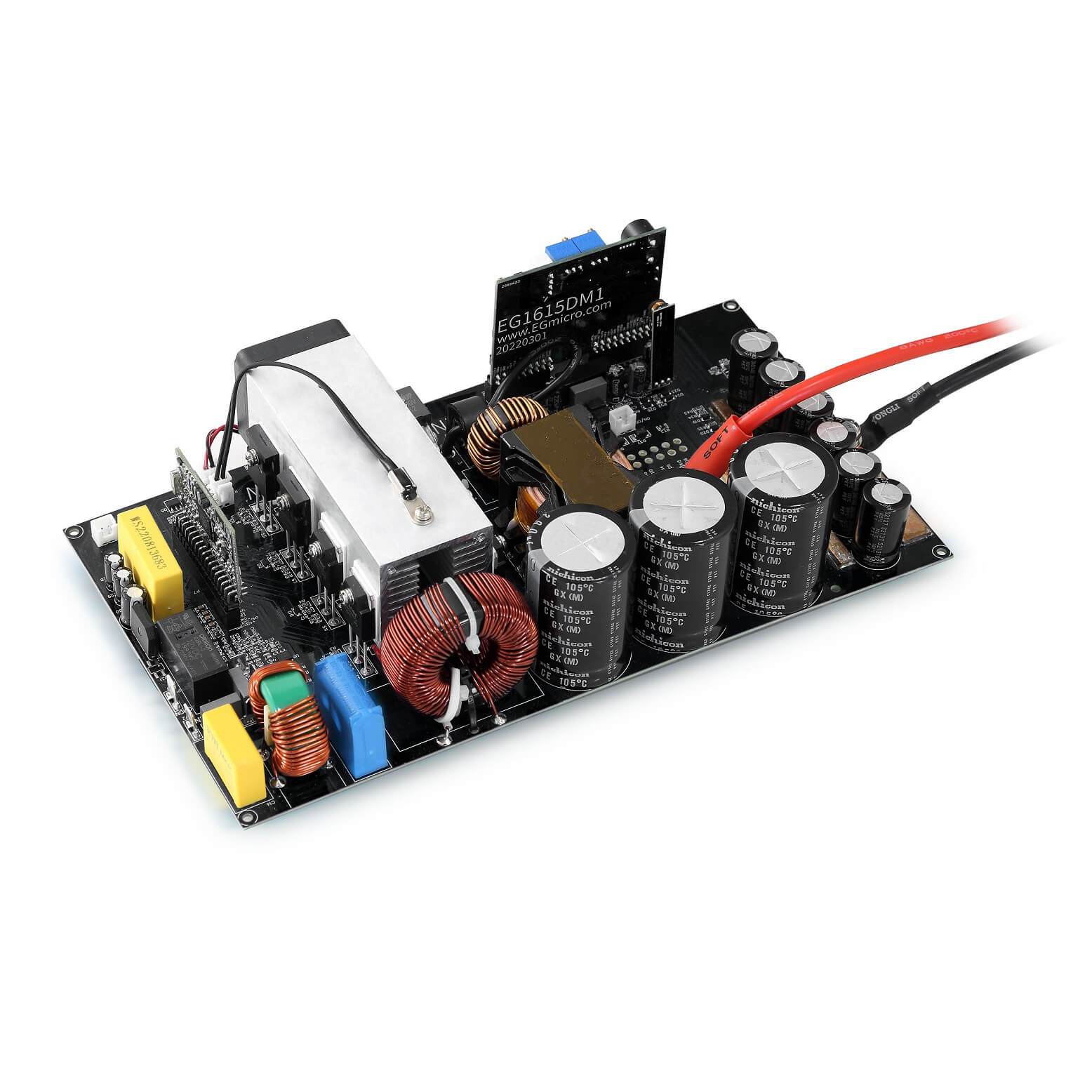

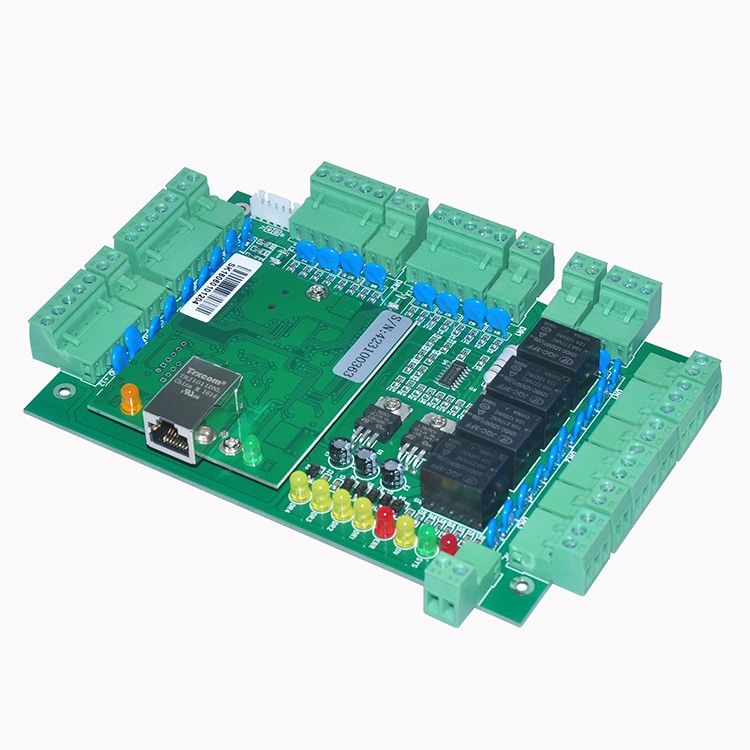

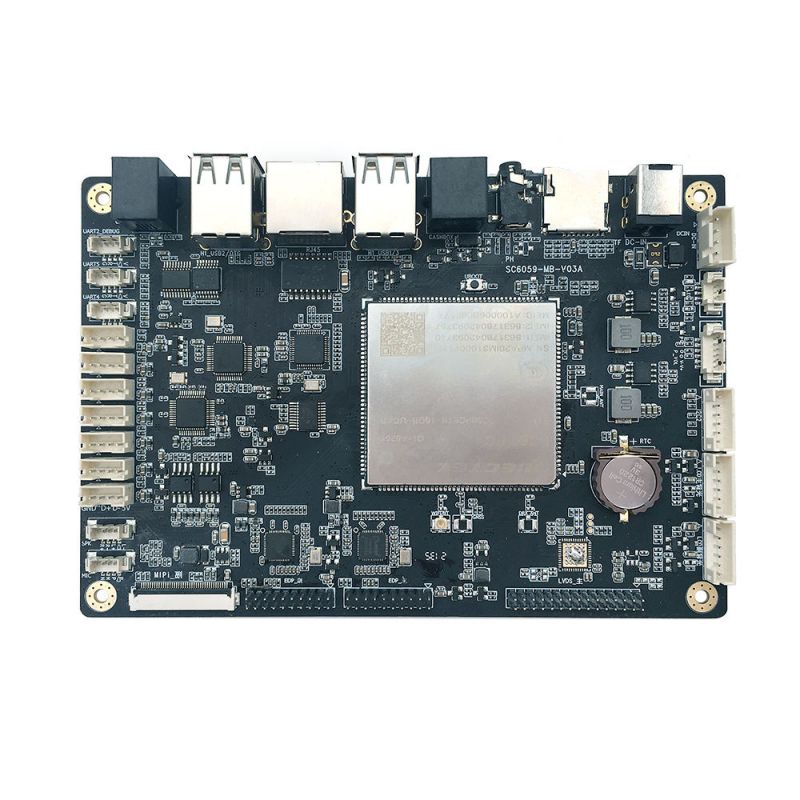

PCB assembly

process |

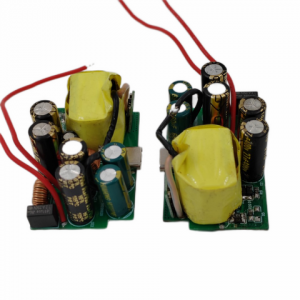

Drilling—–Exposure—–Plating—–Etaching & Stripping—–Punching—–Electrical Testing—–SMT—–Wave Soldering—–Assembling—–ICT—–Function Testing—–Temperature & Humidity Testing |

Key Specifications/Special Features:

O Our Advantage

※ ※ More than 10 years experience of electronic manufacturing sevices for PCB PCBA making

※※ One stop PCBA service | PCB Manufacturing | Components sourcing and PCB assembly to help you easily achieve your electronic products.

※More than 500 customers working with us in telecom ,IOT ,RF, smartcontrol ,security, medical ,industrial, automotive, 3G/4G/5G products.

※ Reasonable and stable price: have established a strong global electronics components supply chain that help us get reasonable and stable price

※ Quality assurance: more than 6years PCBA experienced engineering team and PCBA quality control team to ensure all products come out under control.

※Professional PCBA replace-solution: help customers source professional replace-solution to achieve faster, lower cost with high quality components

pu purchasing agent service

※ No MOQ: Sample available for multilayer PCBs, PCB assemblies and HDI PCBs

※ ※ 100% inspection of all PCBA products

※ ※RFQs answered within 24 hours

※ ※Responses to inquiry within two hours

※ ※Exporting to Europe and North and South America

Landztop is providing one-stop PCBA contract manufacturing service: from PCBA to complete product assembly, including following services to our client:

PCB manufacturing

Components sourcing

PCB assembly

Firmware programming

PCBA functional test

Plastic/Metal case assembly

Our factory has certificated ISO9001, ISO13485, quality management system standard to serve our clients in the telecomunications, automotive electronics, 3G/4G/5G products, IOT products, AI smart control products, RF, networking, security, Inudstrial control, medical Instrument, military products, computer peripherals and other high-teach fields.

FAQ:

1. Is my design files safe when it is sent to you?

Your file is completely safe. Your file will never be shared, and any third party cannot access your design file.

We can sign the NDA before sending the file.

2. Can you produce the original PCB for small batch orders?

Yes, we can produce the original type, but the larger the number, the more cost saved

3. What file format do you accept PCB and PCB assembly?

PCB file: Protel 99se, P-CAD 2001 PCB

Material list: Excel (PDF, Word, TXT)

4. Do you provide after -sales product services for your customers?

Yes, for any quality problem, we will be responsible for solving it at any time.

5. What services do you have?

We mainly focus on OEM & ODM’s electronic contract manufacturing services

(PCB manufacturing, component procurement and PCB assembly services)

In addition to providing IC programming, PCBA function test, cable, box assembly and transportation services