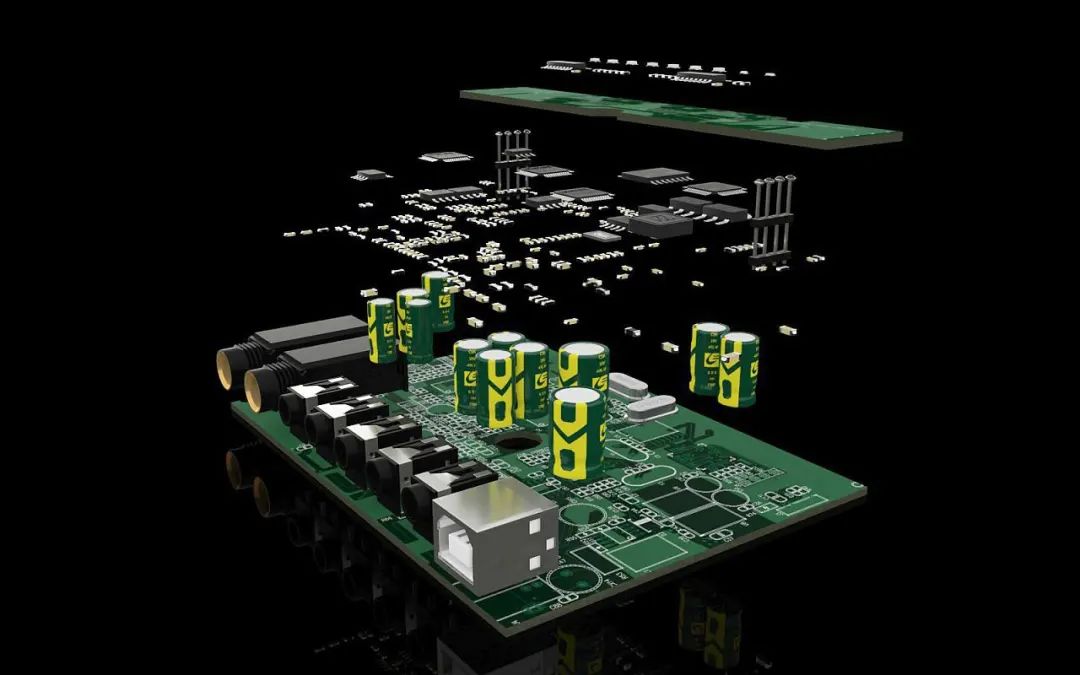

During the manufacturing process of PCB boards, many unexpected situations will occur, such as electroplated copper, chemical copper plating, gold plating, tin-lead alloy plating and other plating layer delamination. So what is the reason for this stratification?

Under the irradiation of ultraviolet light, the photoinitiator that absorbs the light energy is decomposed into the free group that triggers the photopolymerization reaction and forms the body molecule that is insoluble in dilute alkali solution. Under exposure, due to incomplete polymerization, during the development process, the film swelling and softening, resulting in unclear lines and even film falling off, resulting in poor bonding between the film and copper; If the exposure is excessive, it will cause difficulties in development, and it will also produce warping and peeling during the plating process, forming infiltration plating. So it’s important to control the exposure energy; After the surface of the copper is treated, the cleaning time is not easy to be too long, because the cleaning water also contains a certain amount of acidic substances, although its content is weak, but the impact on the surface of the copper can not be taken lightly, and the cleaning operation should be carried out in strict accordance with the process specifications.

The main reason why the gold layer falls off from the surface of the nickel layer is the surface treatment of nickel. The poor surface activity of nickel metal is difficult to obtain satisfactory results. The surface of nickel coating is easy to produce passivation film in the air, such as improper treatment, it will separate the gold layer from the surface of the nickel layer. If the activation is not appropriate in the electroplating, the gold layer will be removed from the surface of the nickel layer and peel off. The second reason is that after activation, the cleaning time is too long, causing the passivation film to be re-formed on the nickel surface, and then to be gilded, which will inevitably produce defects in the coating.

There are many reasons for plating delamination, if you want to make a similar situation in the process of plate production does not occur, it has a significant correlation with the care and responsibility of technicians. Therefore, an excellent PCB manufacturer will conduct high standard training for every workshop employee in order to prevent the delivery of inferior products.

Post time: Apr-07-2024