The selection of PCB materials and electronic components is quite learned, because customers need to consider more factors, such as the performance indicators of components, functions, and the quality and grade of components.

Today, we will systematically introduce how to correctly select PCB materials and electronic components.

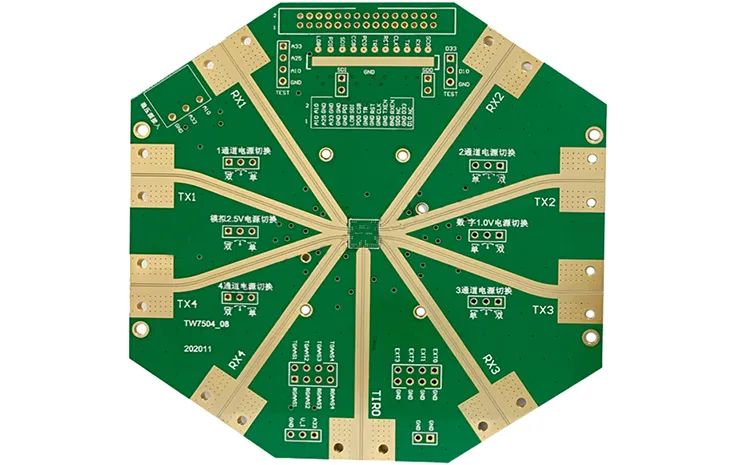

PCB material selection

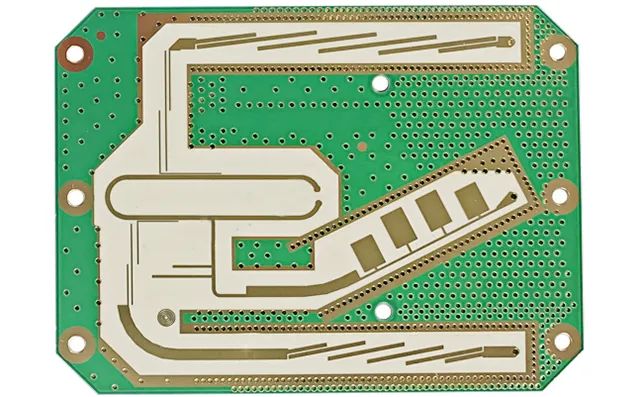

FR4 epoxy fiberglass wipes are used for electronic products, polyimide fiberglass wipes are used for high ambient temperatures or flexible circuit boards, and polytetrafluoroethylene fiberglass wipes are needed for high-frequency circuits. For electronic products with high heat dissipation requirements, metal substrates should be used.

Factors that should be considered when selecting PCB materials:

(1) A substrate with a higher glass transition temperature (Tg) should be appropriately selected, and Tg should be higher than the operating temperature of the circuit.

(2) Low coefficient of thermal expansion (CTE) is required. Due to the inconsistent coefficient of thermal expansion in the direction of X, Y and thickness, it is easy to cause PCB deformation, and it will cause metallization hole fracture and damage components in serious cases.

(3) High heat resistance is required. Generally, PCB is required to have a heat resistance of 250℃ / 50S.

(4) Good flatness is required. The PCB warpage requirement for SMT is <0.0075mm/mm.

(5) In terms of electrical performance, high frequency circuits require the selection of materials with high dielectric constant and low dielectric loss. Insulation resistance, voltage strength, arc resistance to meet the requirements of the product.

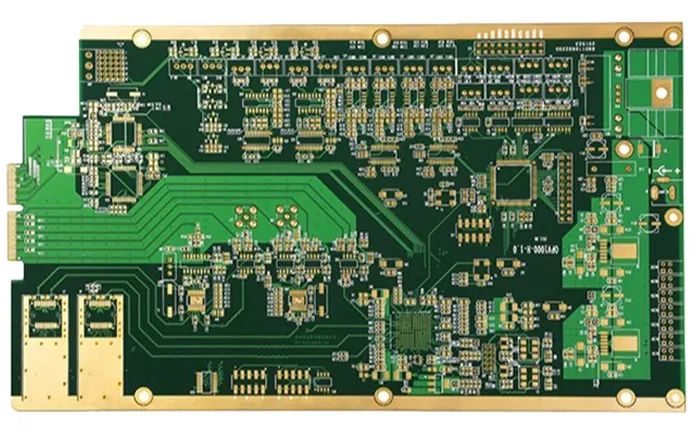

Selection of electronic components

In addition to meeting the requirements of electrical performance, the selection of components should also meet the requirements of surface assembly for components. But also according to the production line equipment conditions and the product process to choose the component packaging form, component size, component packaging form.

For example, when high-density assembly requires the selection of thin small-size components: if the mounting machine does not have a wide-size braid feeder, the SMD device of braid packaging cannot be selected;

Post time: Jan-22-2024