SMT adhesive, also known as SMT adhesive, SMT red adhesive, is usually a red (also yellow or white) paste evenly distributed with hardener, pigment, solvent and other adhesives, mainly used to fix components on the printing board, generally distributed by dispensing or steel screen printing methods. After affixing the components, place them in the oven or reflow furnace for heating and hardening. The difference between it and the solder paste is that it is cured after heat, its freezing point temperature is 150 ° C, and it will not dissolve after reheating, that is to say, the heat hardening process of the patch is irreversible. The use effect of SMT adhesive will vary due to the thermal curing conditions, the connected object, the equipment used, and the operating environment. The adhesive should be selected according to the printed circuit board assembly (PCBA, PCA) process.

Characteristics, application and prospect of SMT patch adhesive

SMT red glue is a kind of polymer compound, the main components are the base material (that is, the main high molecular material), filler, curing agent, other additives and so on. SMT red glue has viscosity fluidity, temperature characteristics, wetting characteristics and so on. According to this characteristic of red glue, in the production, the purpose of using red glue is to make the parts firmly stick to the surface of the PCB to prevent it from falling. Therefore, the patch adhesive is a pure consumption of non-essential process products, and now with the continuous improvement of PCA design and process, through hole reflow and double-sided reflow welding have been realized, and the PCA mounting process using the patch adhesive is showing a trend of less and less.

The purpose of using SMT adhesive

① Prevent components from falling off in wave soldering (wave soldering process). When using wave soldering, the components are fixed on the printed board to prevent the components from falling off when the printed board passes through the solder groove.

② Prevent the other side of the components from falling off in the reflow welding (double-sided reflow welding process). In the double-side reflow welding process, in order to prevent the large devices on the soldered side from falling off due to the heat melting of the solder, the SMT patch glue should be made.

③ Prevent the displacement and standing of components (reflow welding process, pre-coating process). Used in reflow welding processes and pre-coating processes to prevent displacement and riser during mounting.

④ Mark (wave soldering, reflow welding, pre-coating). In addition, when printed boards and components are changed in batches, patch adhesive is used for marking.

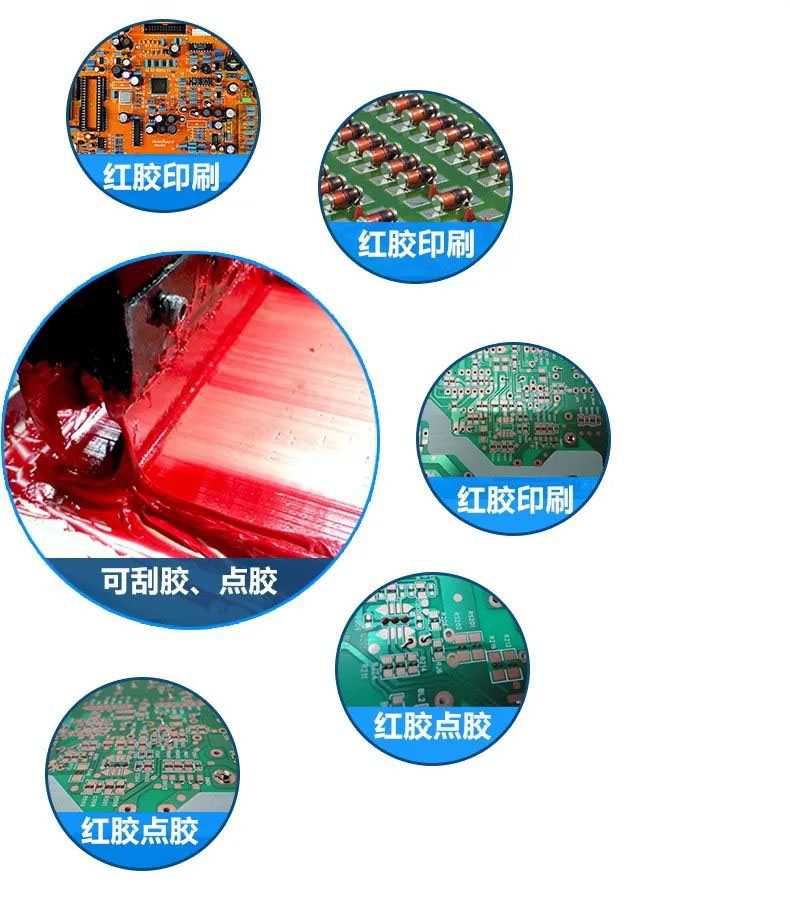

SMT adhesive is classified according to the mode of use

a) Scraping type: sizing is carried out through the printing and scraping mode of steel mesh. This method is the most widely used and can be used directly on the solder paste press. The steel mesh holes should be determined according to the type of parts, the performance of the substrate, the thickness and the size and shape of the holes. Its advantages are high speed, high efficiency and low cost.

b) Dispensing type: The glue is applied on the printed circuit board by dispensing equipment. Special dispensing equipment is required, and the cost is high. Dispensing equipment is the use of compressed air, the red glue through the special dispensing head to the substrate, the size of the glue point, how much, by the time, pressure tube diameter and other parameters to control, dispensing machine has a flexible function. For different parts, we can use different dispensing heads, set parameters to change, you can also change the shape and quantity of the glue point, in order to achieve the effect, the advantages are convenient, flexible and stable. The disadvantage is easy to have wire drawing and bubbles. We can adjust the operating parameters, speed, time, air pressure, and temperature to minimize these shortcomings.

SMT Patching Typical CICC

be careful:

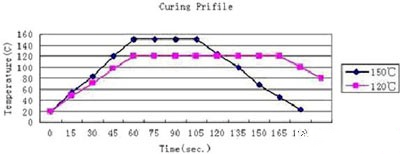

1. The higher the curing temperature and the longer the curing time, the stronger the adhesive strength.

2. Because the temperature of the patch glue will change with the size of the substrate parts and the sticker position, we recommend finding the most suitable hardening conditions.

SMT patch glue storage

It can be stored for 7 days at room temperature, storage is greater than June at less than 5 ° C, and can be stored more than 30 days at 5-25 ° C.

SMT patch gum management

Because the SMT patch red glue is affected by the temperature, the characteristics of the viscosity, liquidity, and wetness of the SMT, the SMT patch red glue must have certain conditions and standardized management.

1) Red glue must have a specific flow number, and numbers according to the number of feeding, date, and types.

2) Red glue should be stored in a refrigerator of 2 to 8 ° C to prevent the characteristics of the characteristics due to temperature changes.

3) Red glue recovery requires 4 hours at room temperature, and is used in the order of advanced first.

4) For point replenishment operations, the glue tube red glue should be designed. For the red glue that has not been used at one time, it should be put back to the refrigerator to save.

5) Fill in the recording recording form accurately. The recovery and warming time must be used. The user needs to confirm that the recovery is completed before it can be used. Usually, red glue cannot be used.

SMT patch glue’s process characteristics

Connection intensity: SMT patch glue must have a strong connection strength. After being hardened, the temperature of the weld melt is not peeled.

Point coating: At present, the distribution method of the printing board is mostly applied, so it is required to have the following performance:

① Adapt to various stickers

② Easy to set the supply of each component

③ Simply adapt to replacement component varieties

④ Point coating stable

Adapt to high -speed machines: The patch glue now must meet the high -speed coating and the high -speed patch machine. Specifically, the high -speed dot is drawn without drawing, and when the high -speed paste is installed, the printed board is in the process of transmission. The stickiness of tape gum must ensure that the component does not move.

Ritting and falling: Once the patch glue is stained on the pad, the component cannot be connected to the electrical connection with the printed board. To avoid pollution pads.

Low temperature curing: When solidifying, first use the peak -welded insufficient heat -resistant inserted components to be welded, so it is required that the hardening conditions must meet the low temperature and short time.

Self -adjustability: In the re -welding and pre -coating process, the patch glue is solidified and fixed components before the weld is melted, so it will hinder the sinking of the meta and self -adjustment. For this point, manufacturers have developed a self -adjustable patch glue.

SMT patch glue common problems, defects and analysis

Insufficient thrust

The thrust strength requirements of the 0603 capacitor are 1.0kg, the resistance is 1.5kg, the thrust strength of the 0805 capacitor is 1.5kg, and the resistance is 2.0kg.

Generally caused by the following reasons:

1. Insufficient glue.

2. There is no 100%solidification of the colloid.

3. PCB boards or components are polluted.

4. The colloid itself is crispy and has no strength.

Tentile unstable

A 30ml syringe glue needs to be hit by pressure tens of thousands of times to complete, so it is required to have an extremely excellent tactileness itself, otherwise it will cause unstable glue points and less glue. When welding, the component falls off. On the contrary, excessive glue, especially for tiny components, is easy to stick to the pad, hindering electrical connection.

Insufficient or leakage point

Reasons and countermeasures:

1. The net board for printing is not regularly washed, and ethanol should be washed every 8 hours.

2. The colloid has impurities.

3. The opening of the mesh is not reasonable or too small or the glue gas pressure is too small.

4. There are bubbles in the colloid.

5. Plug the head to block, and immediately clean the rubber mouth.

6. The preheating temperature of the point of the tape is insufficient, and the temperature of the tap should be set at 38 ° C.

Brushed

The so -called brushed is that the patch is not broken when the dicture, and the patch is connected in the dot -headed direction. There are more wires, and the patch glue is covered on the printed pad, which will cause poor welding. Especially when the size is large, this phenomenon is more likely to occur when you apply your mouth. Settlement of slice glue brushes is mainly affected by its main ingredient resin brushes and settings of the point coating conditions:

1. Increase the tide stroke to reduce the movement speed, but it will reduce your production auction.

2. The less low viscosity, high -touch material, the smaller the tendency of drawing, so try to choose this type of tape.

3. Slightly increase the temperature of the thermal regulator, and adjust it to a low viscosity, high -touch and degeneration patch glue. At this time, the storage period of the patch glue and the pressure of the tap head should be considered.

Collapse

The liquidity of the patch glue causes collapse. The common problem of collapse is that it will cause collapse after being placed for a long time. If the patch glue is expanded to the pad on the printed circuit board, it will cause poor welding. And for those components with relatively high pins, it cannot contact the main body of the component, which will cause insufficient adhesion. Therefore, it is easy to collapse. It is predicted, so the initial setting of its point coating is also difficult. In response to this, we had to choose those who were not easy to collapse. For the collapse caused by dotted for too long, we can use the patch glue and solidification in a short period of time to avoid.

Component offset

Component offset is a bad phenomenon that is prone to high -speed patch machines. The main reason is:

1. It is the offset generated by the X-Y direction when the printed board is moving at a high speed. This phenomenon is prone to occur on the component with small glue coating area. The reason is caused by the adhesion.

2. It is inconsistent with the amount of glue under the component (for example: 2 glue points below the IC, a glue point is large and a small glue point). When the glue is heated and solidified, the strength is uneven, and one end with a small amount of glue is easy to offset.

Welding part of the peak

The cause of the cause is very complicated:

1. Insufficient adhesion for patch glue.

2. Before the welding of the waves, it was hit before welding.

3. There are many residues on some components.

4. High temperature impact of colloidity is not resistant to high temperature

Patch glue mixed

Different manufacturers are very different in chemical composition. Mixed use is prone to cause a lot of adverse: 1. Fixed difficulty; 2. Insufficient adhesion; 3. Severe welded parts over the peak.

The solution is: thoroughly cleaning the mesh, scraper, and point -headed head, which are easy to cause mixed use to avoid mixing the use of different brands of patch glue.

Post time: Jun-19-2023