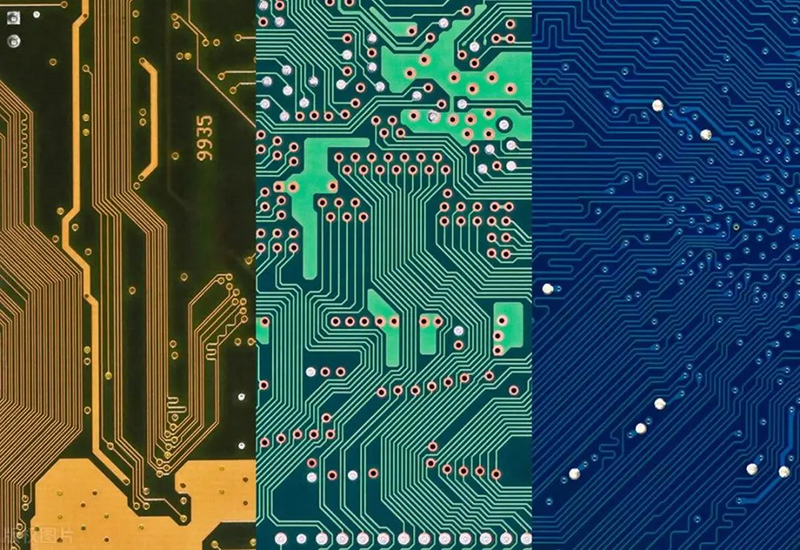

When we carry out PCB proofing, we will see the problem of choosing how to splice (that is, PCB circuit board connecting board), so today we will tell you about the content of PCB connecting board

There are usually several PCB connecting modes

1. V-shaped cutting: By cutting a V-shaped groove at the edge of the board, and then breaking the board to separate.

2. Copper foil bridge connection: Reserve some prominent parts on the board, through which multiple plates can be connected together to complete the board.

3. Separate connecting plates: Leave some small connecting points between the plates, and then separate the plates by breaking these connecting points.

4. Panel: Place multiple PCB designs on a large substrate, and then separate them using mechanical or V-Scoring methods.

Know the above four PCB connecting ways, I believe you will use it freely? If it is not clear, we will send you the use and advantages of PCB connecting method.

1. Uses and advantages

1. Improve production efficiency: Connected boards can combine multiple PCB designs together to reduce manufacturing time and labor costs through batch processing. This is especially important in mass production.

2. Reduce manufacturing costs: The board can maximize the use of raw materials and reduce waste generation. At the same time, the connecting plate can reduce the processing steps and the number of equipment uses, which helps to reduce manufacturing costs.

3. Convenient assembly and testing: the board technology makes the assembly process more simplified and efficient. Multiple PCBS can be installed and wired simultaneously, reducing assembly time. In addition, the board facilitates rapid batch testing and debugging.

4. Improve product quality and reliability: By connecting the board, you can ensure that the connection and alignment between multiple PCBS are accurate, reducing the risk of failure caused by poor connection and misalignment of the line. At the same time, the board can provide better electrical and mechanical stability.

5. Facilitate subsequent maintenance and repair: If multiple PCBS are integrated in a single board, maintenance and repair only need to deal with a whole, and do not need to deal with each PCB separately. This saves time and effort.

In general, the main advantages of PCB connecting methods are to improve production efficiency, reduce manufacturing costs, simplify assembly and testing processes, and improve product quality and reliability. This makes the board a common manufacturing method in mass production and high-quality electronic products.

Post time: Nov-04-2023