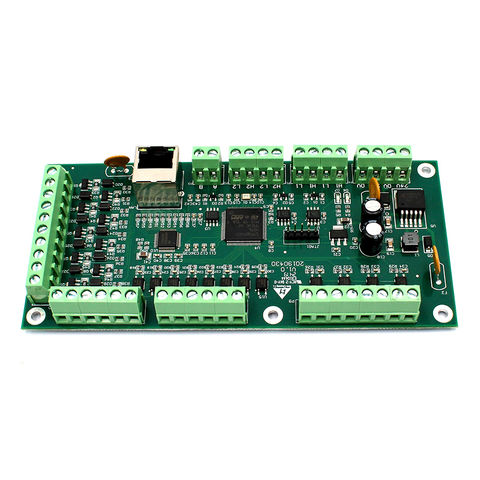

Keyboard pcb board used on Medical Device with BGA assembly with ISO 13485

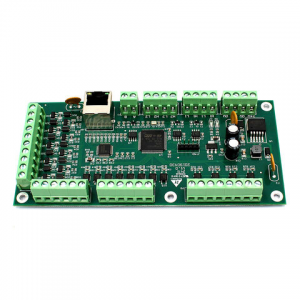

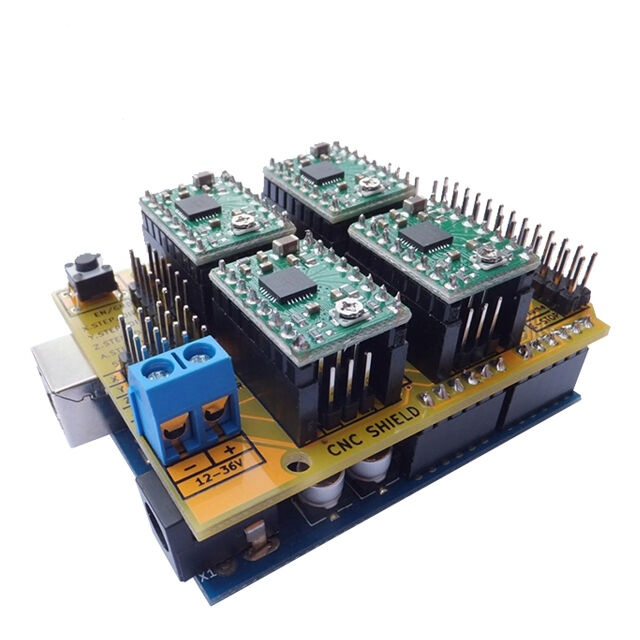

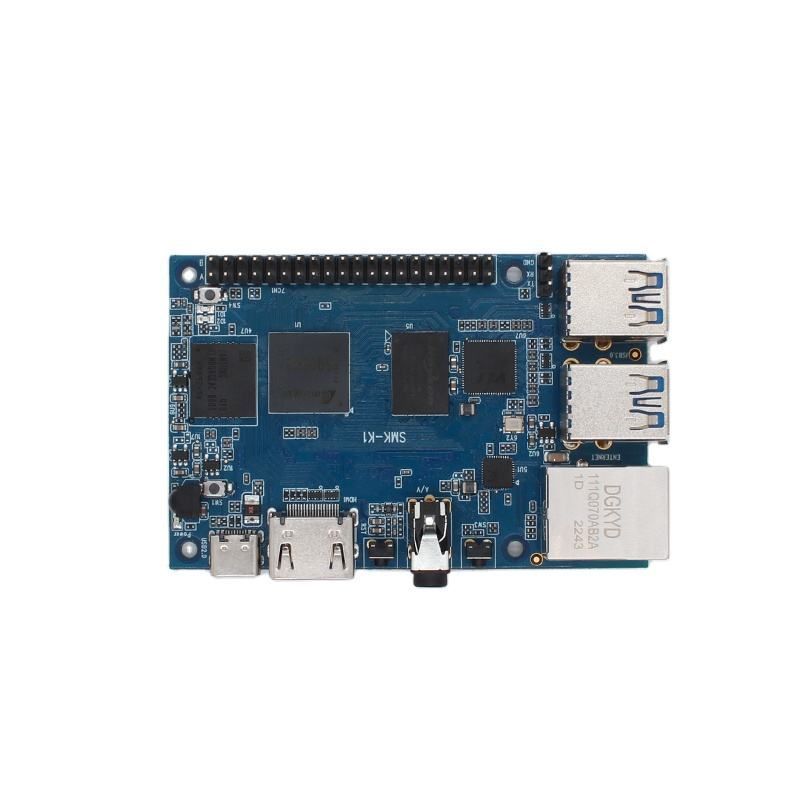

From complex multi-layer board to double sided surface mount design, our goal is to provide you a quality product that meets your requirements and is the most cost-effective to manufacture

Our experience in IPC class III standards, very stringent cleanliness requirements, heavy copper and production tolerances allow us to provide our customers exactly what they need for their end product

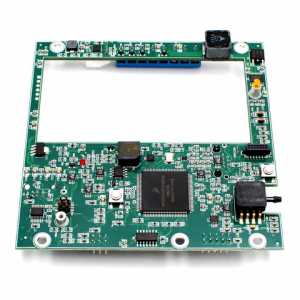

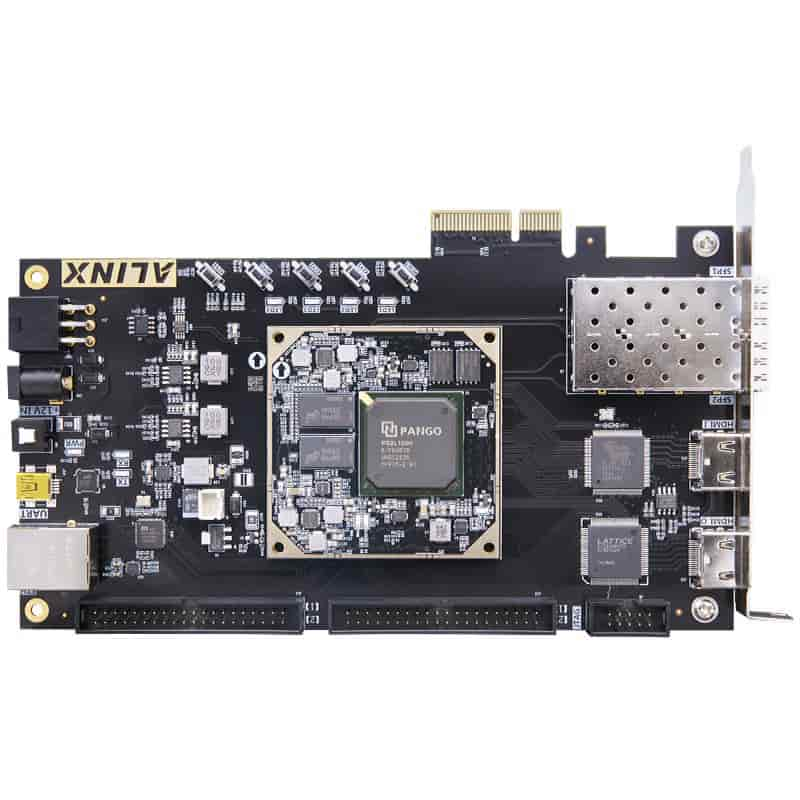

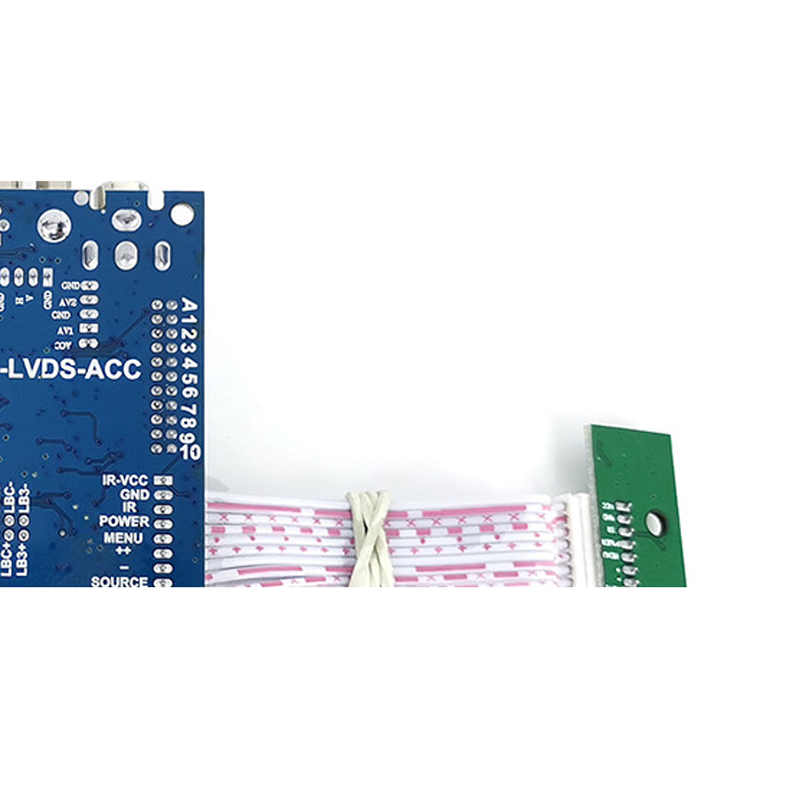

Advanced technology products:

Backplanes, HDI boards, high-frequency boards, high TG boards, halogen-free boards, flexible and rigid-flex boards, hybrids and any boards with applications in high-tech products

20-layer PCB, 2 mil line width spacing:

Our 10-year manufacturing experience, high-precision equipment and testing instruments enables VIT to produce 20-layer rigid boards and rigid-flex circuits up to 12 layers

Backplane thicknesses up to .276 (7mm), aspect ratios up to 20:1, 2/2 line/space and impedance controlled designs are produced daily

Products and technology application:

Apply to communications, aerospace, defense, IT, medical equipment, precision test equipment and industrial control companies

Standard criteria for PCBs processing: inspection and test criteria will be based upon IPC-A-600 and IPC-6012, class 2 unless otherwise specified on customer drawings or specifications

PCB design service: VIT also can provide the PCB design service to our customers

Sometimes, our customers only give us 2D file or just an idea, then we shall design the PCB, layout and make the Gerber file for them

| Item | Description | Technical capabilities |

| 1 | Layers | 1-20 layers |

| 2 | Max board size | 1200x600mm (47x23") |

| 3 | Materials | FR-4, high TG FR4, halogen free material, Rogers, Arlon, PTFE, Taconic, ISOLA, ceramics, aluminum, copper base |

| 4 | Max board thickness | 330mil (8.4mm) |

| 5 | Min inner line width/space | 3mil (0.075mm)/3mil (0.075mm) |

| 6 | Min outer line width/space | 3mil (0.75mm)/3mil (0.075mm) |

| 7 | Min finish hole size | 4mil (0.10mm) |

| 8 | Min via hole size and pad | Via: diameter 0.2mm Pad: diameter 0.4mm HDI <0.10mm via |

| 9 | Min hole tolerance | ±0.05mm (NPTH), ±0.076mm (PTH) |

| 10 | Finished hole size tolerance (PTH) | ±2mil (0.05mm) |

| 11 | Finished hole size tolerance (NPTH) | ±1mil (0.025mm) |

| 12 | Hole position deviation tolerance | ±2mil (0.05mm) |

| 13 | Min S/M pitch | 3mil (0.075mm) |

| 14 | Solder mask hardness | ≥6H |

| 15 | Flammability | 94V-0 |

| 16 | Surface finishing | OSP, ENIG, flash gold, immersion tin, HASL, tin-plated, immersion silver,carbon ink, peel-off mask, gold fingers (30μ"), immersion silver (3-10u"), immersion tin (0.6-1.2um) |

| 17 | V-cut angle | 30/45/60°, tolerance ±5° |

| 18 | Min V-cut board thickness | 0.75mm |

| 19 | Min blind/buried via | 0.15mm (6mil) |